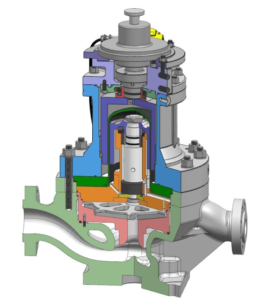

The vertically mounted GSPV pump provides all of the benefits of a magnetic drive sealless pump in a compact package that is particularly suitable for use where space is limited.

The GSPV meets all of the requirements of API 685 2nd edition, making it ideal for booster packages, pipeline injection, heavy duty chemical applications, monitoring and sampling packages, especially those where space is at a premium, such as offshore installations.

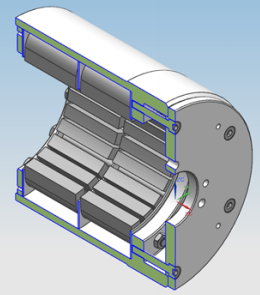

With a wide operating envelope of up to 40 Bar / 580 psi and flow rates up to 235 m³/hour /1250 gpm, the GSPV is available in nine hydraulics, which are split between two frame (magnetic coupling) sizes to suit different power requirements, with the option of ZeroLoss® shells in all configurations.

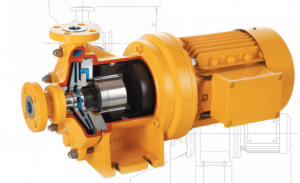

HMD also has a range of non-API vertical in-line units for use in various chemical and general industry applications. Further details can be seen at www.hmdkontro.com.

A sister product, the LMV 801S, is also available, which is dimensionally interchangeable with the Sundyne LMV and VIP 801 pumps and will simply “drop-in” to existing pipework, making sealless upgrades possible without the need to modify pipe and foundation layout, to help meet increasingly stringent emissions regulations.