The importance of health & safety at HMD Kontro is never underestimated and it is something that is taken extremely seriously. Employees, sub-contractors, customers, visitors and any members of the public are all taken into consideration when ensuring the company’s premises are as safe as possible and so revitalising the team was considered very important and vital. Consequently, a company election was held to appoint new Health & Safety representatives. The outcome was that HMD Kontro now has a team made up predominantly of new employee safety reps who will work alongside the two existing and experienced representatives.

Promoting free-flowing and candid conversations

Bi-monthly committee meetings are planned with the most recent one attended by the newly appointed representatives. All in all, it was very successful as everyone came well prepared and all brought something to the table allowing for a free-flowing and candid discussion and if there are any issues or concerns that arise between meetings, these can be raised with the EHS manager. It is hoped that the new reps will be as proactive as possible and already they are being utilised for incident investigation. This will not only give them an insight into a range of situations, but also enable them to give their viewpoint on activities and solutions. Further training will be provided to help the reps settle into and be confident in their new roles.

Above (from left to right): Andy Mann, Liane Emery, Andy Schlotter, Claire Penfold, Brian Cordingley.

What do the Health & Safety Reps say?

Brian Cordingley – Storeman – “My aim is to help the team make HMD Kontro a safe and enjoyable place to work.”

Claire Penfold – Factory, Shop Floor – “I want to understand more about the health and safety side of the business. It will enable me to help my colleagues and to also assist the company in recognising where workplace related problems could occur. I’ll be a small part of the team to help overcome and solve problems that may arise.”

Liane Emery – Service Co-ordinator – “Having been with HMD Kontro for twelve years, I jumped at the opportunity to be a Health & Safety Rep. My aim is to help David and the team bring awareness and make the work areas safer places to be, which will ensure better safety for everyone.”

Andy Schlotter – Paint Sprayer – “I became a rep four years ago with my main reason being that I felt quite strongly about safety in the work place and wanted to try to improve people’s awareness of it and help in some small way. Everyone should be aware of how dangerous it can be working in a manufacturing and engineering environment. As I have spent all my working life in this industry, I feel I do know about the types of dangers it can bring. By educating others, I feel I’ve helped in my own way. The paint shop also brings with it some unpleasant and dangerous substances and so this has made me very aware about being vigilant in my every day job and hopefully I can make others aware of good practices.”

Andrew Mann IEng MIMechE – Senior Product Engineer – “I became a Health & Safety Rep about five years ago and have now been re-elected for a second five year term. I took on the role to help maintain, support and improve the health and safety of our workplace in order to ensure a safe working environment for all HMD employees. I bring to the role previous experience, which I hope will help the new members of the ‘safety team’. I want to continue and encourage staff to raise safety concerns, whilst broadly assisting in the general overview of the company safety systems ensuring we all go home safely at the end of each working day. I would like to specialise my Health & Safety representative role in the Display Screen Equipment (DSE) regulations and assessment.”

Looking after the mental health of employees

Mental health is a big issue in the workplace today and consequently, HMD Kontro also has two mental health first aiders onsite. These roles are currently completely separate from the safety representative roles although there is nothing to prevent a member of staff having both positions should they wish to put themselves forward when there is a vacancy.

HMD Kontro – safe pumps and a safe place to work

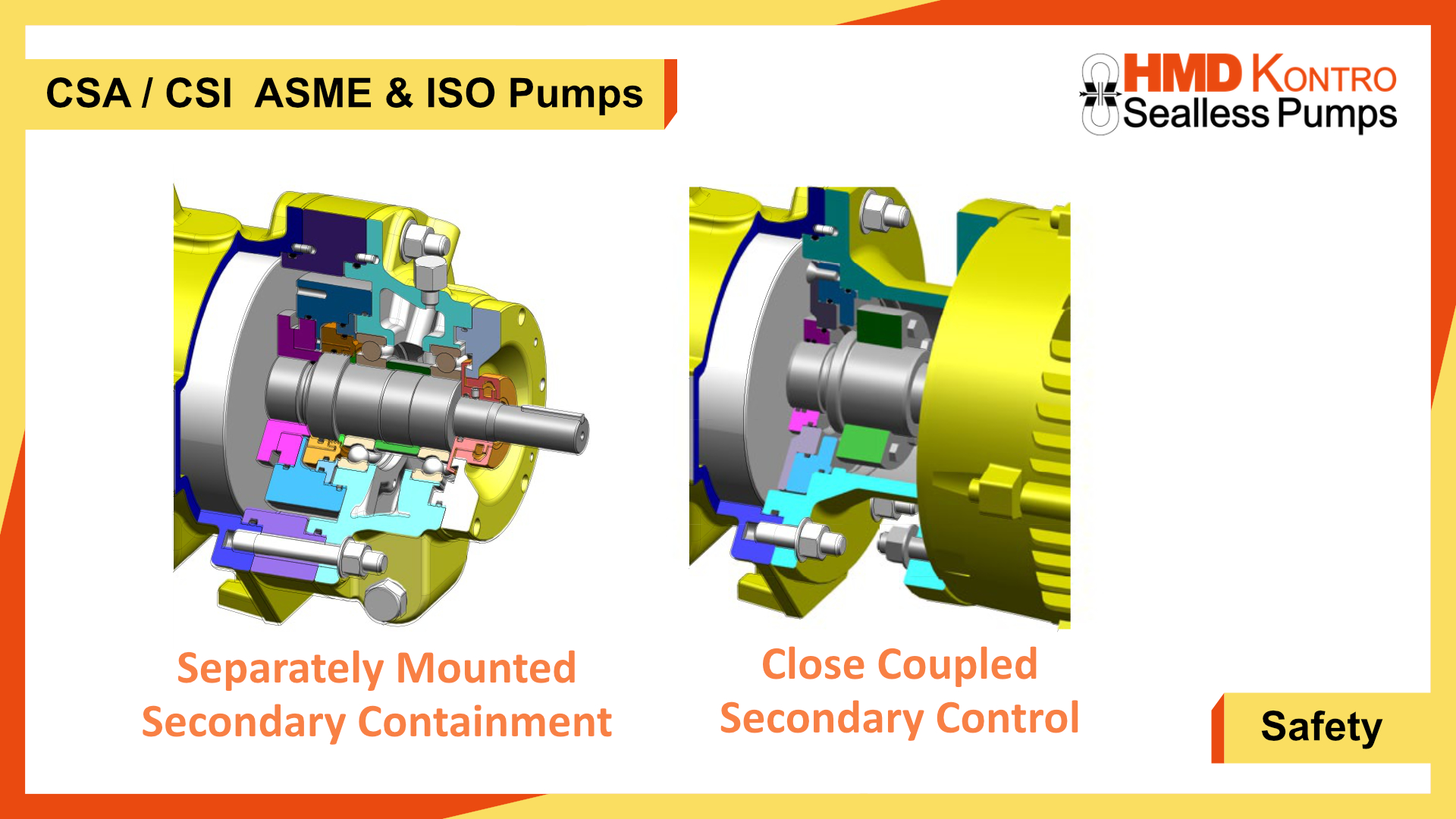

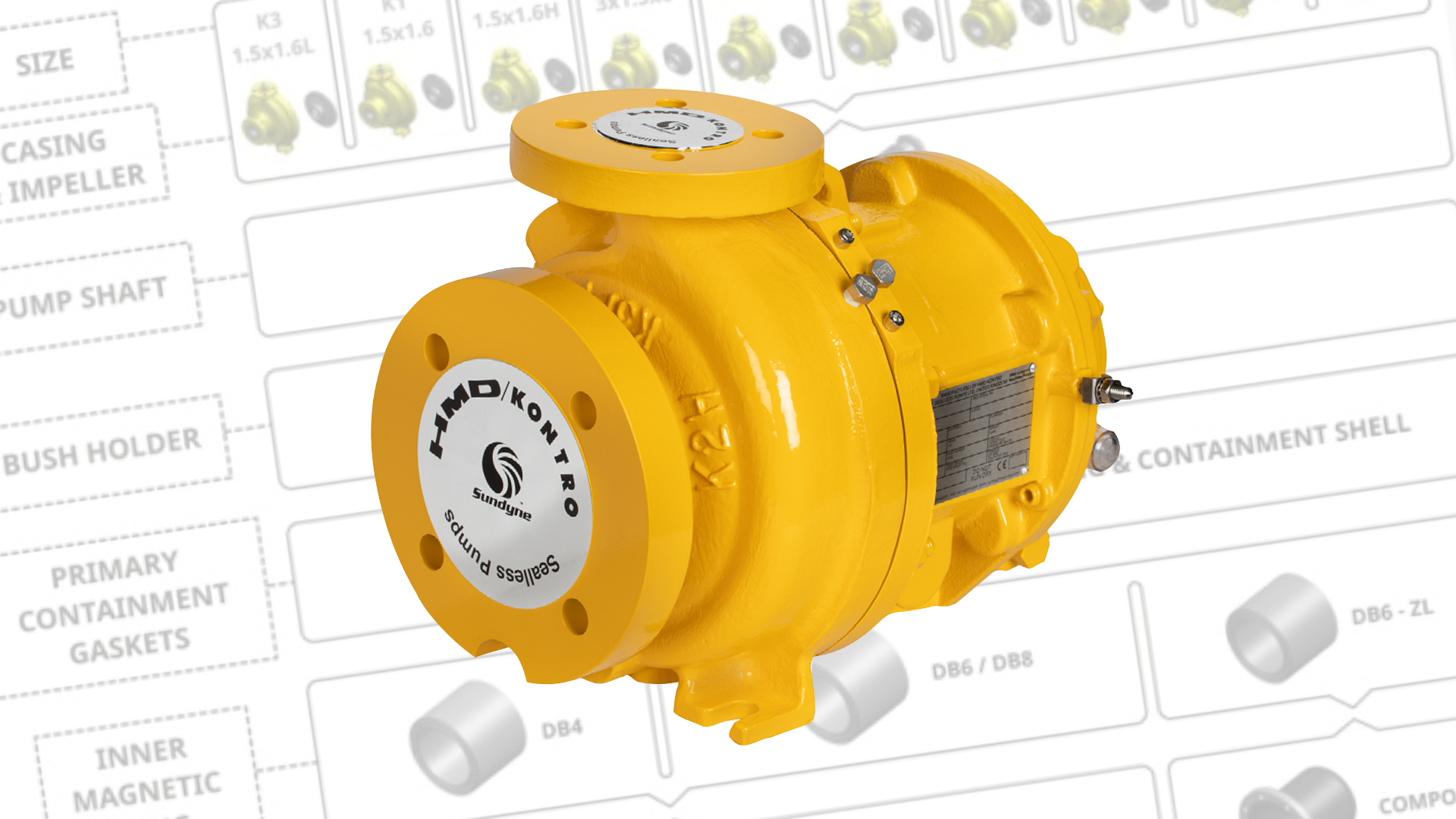

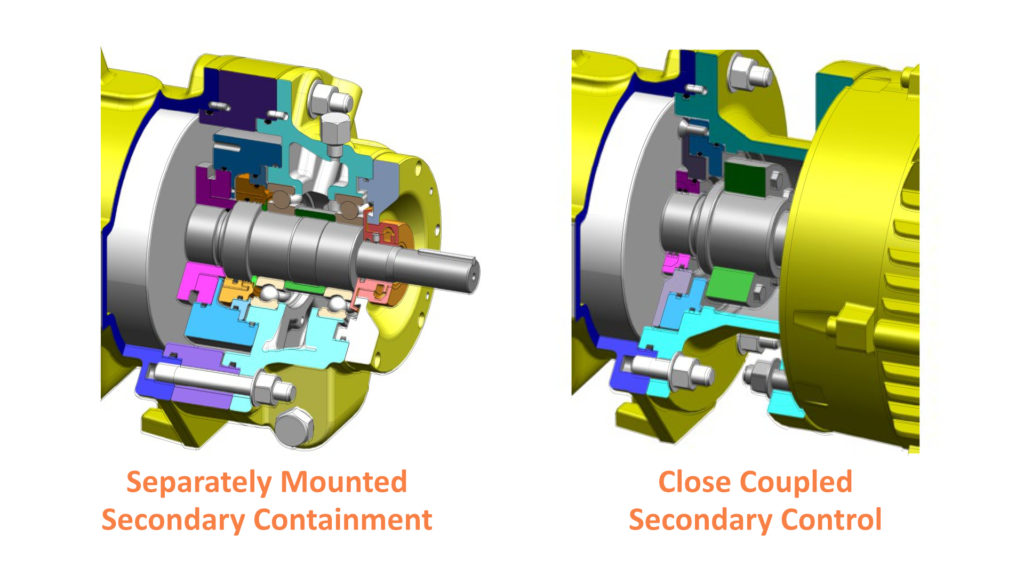

With the new appointments, HMD Kontro now has two office reps and two factory reps. Despite an imminent retirement, one of the HMD Kontro Health & Safety reps is staying on as part of the team in the role of mentor for the new appointees and will be working alongside them to pass on valuable information and lessons that have been learned over the years. HMD Kontro sealless pumps are inherently safe thanks to them being completely leak free and this fits perfectly with the company’s focus on site safety.