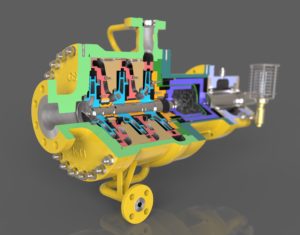

Essentially, sealless pumps are centrifugal pumps without packed glands or seals. Instead of a seal, there is a static containment shell or shroud, which forms a completely sealed liquid end or pressure boundary.

Prime mover energy is transmitted to the sealed liquid end by a bank of external magnets, which pass force through the containment shell to the inner magnets attached to the impeller shaft, meaning there is no risk of leaks or emissions.

Sealless v Sealed Pumps

It’s necessary to understand what a mechanical seal is to differentiate between the two types of pump. Mechanical seals are designed to maintain their sealing capability by leaking small amounts of fluid in order to keep the seal faces lubricated.

Mechanical seals are widely regarded as the weakest point in any pumping system. In fact, they account for 80% of all pump failures, with the remainder being leakage through static seals such as gaskets or O Rings and bearing failure.

Seals, like bearings, will ultimately wear and, as they wear, the seal faces lose their effectiveness and liquid loss through the seal increases. These fugitive emissions can be costly, resulting in lost time and money, as well as reduced worksite and environmental safety.

WHAT makes a HMD Kontro Sealless Pump different?

- Welded metal containment shell to ASME VIII pressure vessel standards

- Optional ZeroLoss® shell. To improve efficiency and reduce life cycle costs

- Dynamically balanced rotating parts for smooth operation and longevity

- Modular cartridge construction reducing maintenance time

- Many common components reducing spare part inventory

- Fully encapsulated outer magnet ring for protection and easy cleaning

How HMD Kontro can help you with your pump requirements

HMD Kontro has a comprehensive range of magnetic drive sealless pumps designed to perform in most climate extremes and in many applications to help you revolutionise your process workflow. To find out more please click here.