CSA/CSI Modularity = Versatility / Reliability / Safety / Serviceability / Availability

The safety of your staff team and eliminating or minimising the impact of manufacturing and other operations on both the local and wider environment is an essential, legal and moral obligation. The containment shell in a magnetic drive pump provides a complete mechanical barrier, preventing leaks, escapes and emissions. There is no reliance on any internal or external seal system or method of prevention.

When it comes to applications that involve toxic, fine, corrosive, aggressive and valuable liquids, our new CSA (ASME) / CSI (ISO) magnetic drive pumps for chemical and industrial processes deliver the ultra-safe, dependable, and reliable performance that engineers demand and that both environmental health and safety, plus industrial regulations, require.

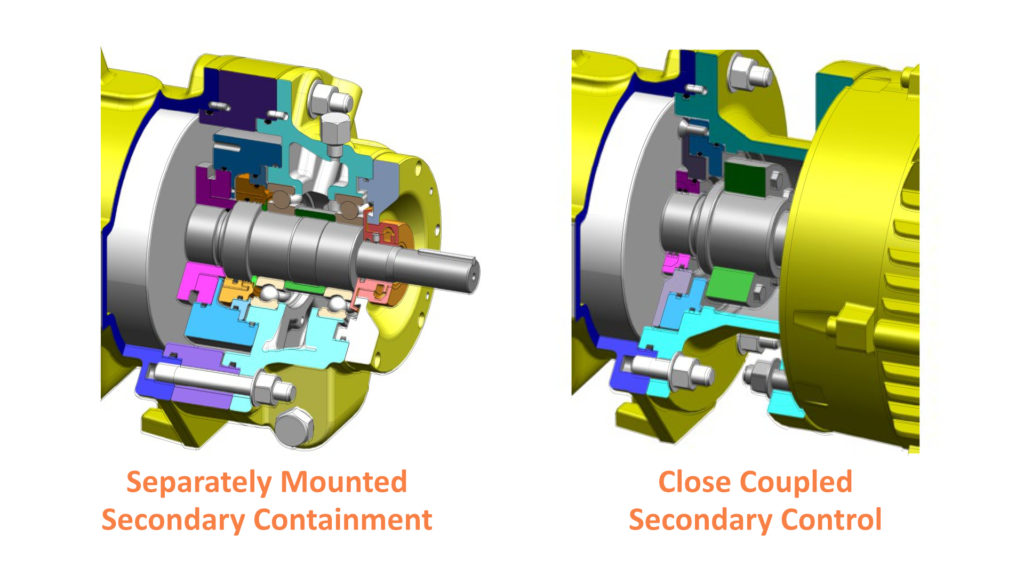

In certain highly challenging applications, compliance with stringent standards calls for a secondary control or containment option to be available, completely eliminating the possibility of a leak of pumped product to escape, in the highly unlikely event of a containment shell failure. In the CSA / CSI product line we have taken the secondary control / containment options further by not only ensuring both options are available on separately mounted pumps but also on close-coupled units, which we believe is unique to HMD Kontro.

The new HMD Kontro CSA (ASME) / CSI (ISO) sealless pump range is specifically designed to be completely leak and emission-free, keeping the pumping media completely enclosed within the body of the pump, exactly where it should be.

Please click through for more information on the new CSA / CSI range including detailed product specifications, animation, podcasts etc.