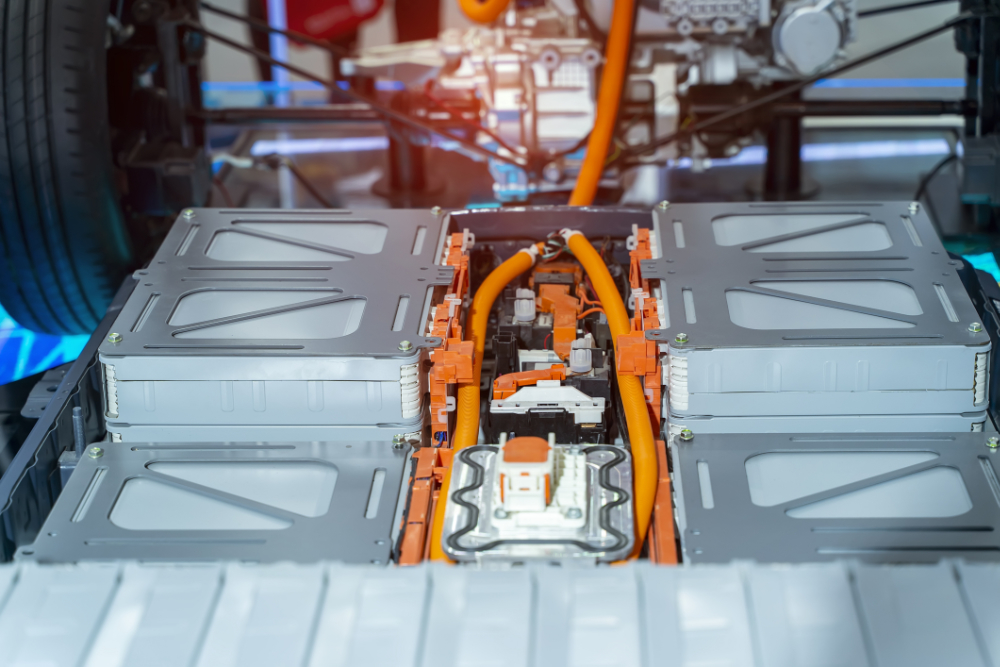

As battery manufacturing evolves, the pursuit of greater battery production capacity within plants, requires the maintenance of efficient and reliable manufacturing processes.

HMD Kontro have supported multiple global leaders in lithium-ion battery manufacturing, where the circulation or transfer of hazardous chemicals is intrinsic to daily manufacturing processes.

We understand some of the key priorities for the battery manufacturing industry when it comes to pumping liquids:

- Careful handling of flammable, combustible, or toxic chemicals

- Reliable solutions that deliver high operational uptime and require minimal maintenance

- Responsive and flexible global supply with quick delivery capability to worldwide manufacturing plants

- Compliance to industry standards including ASME B73.3, ISO 2858 / 15783, API 685 and ATEX

Battery manufacturers are operating in an industry which is experiencing unprecedented changes in demand. As specialists in the provision of magnetic drive pumps, HMD Kontro sealless magnetic drive pumps provide an effective alternative to traditional mechanical seal pumps by offering:

- Complete fluid containment

- No seals or seal support systems

- Engineering design prioritising protection for human health and safety

- Environmental compliance and energy efficiency

- Increased MTBF and lower operation costs

Pumping hazardous chemicals requires careful handling and consideration of all the risks involved.

To find out more about a safe, leak-free sealless magnetic drive pumps, download the leaflet ‘Delivering Sealless Pump Solutions to the Global Battery Manufacturing Industry’

If you would like further information, please leave your details below and a member of our team will be in touch!