Chemical Processing

- Chlor-Alkali

- Pesticides

- Insecticides

- Herbicides

- Fertilizer

Hydrocarbon Processing

- Sour water

- Sulfuric acid

- Benzene

- Xylene

- Toluene

Upstream

- Produced water

- LACT

It is vital for accuracy when checking the density of process fluids in a high-pressure pipeline and HPGS pumps are very suitable for this. Process engineers are thus able to utilise the HPGS pump on pipeline skids in order to take out a sample of the fluid from the main product stream from where the sample is conveyed through a densitometer designed to analyse the fluid, after which it is returned to the main pipeline.

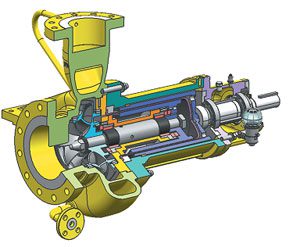

The HPGS sealless magnetic drive pump can withstand system pressures of up to 2680 psi (185 bar) and is available with 7 hydraulics. It comes with a range of synchronous magnet drives, which are rated for prime mover performance. Standard construction is stainless steel with silicon carbide internal bearings although other metallic materials are also possible.

HPGS sealless magnetic drive pumps from HMD Kontro comply with all specifications required by the oil, gas, petroleum and heavy chemical industries and this pump is typically used in toxic, aggressive, hot, crystallising and high value processes.

Benefits of the HMD Kontro HPGS Pump:

| Flows to | 72 m³/hr (317 gpm) |

| Heads to | 93 m (305 ft) |

| Pressures to | 185 bar / 2,680 psi |

| Temperature Range | -40 to 260°C (-40 to 500°F) |

|

Chemical Processing

Hydrocarbon Processing

Upstream

|

Aquatic and Marine

Battery Manufacturing

Biofuels

Food and Beverage

Mining

|

Pharmaceutical

Pulp and Paper

Semiconductor Manufacturing

Steel Finishing, Pickling, Etching and Plating

Water and Wastewater Treatment

|

Product Security – Magnetic drive sealless pumps are the safest and most robust means for liquid transfer. By eliminating the seal, the primary opportunities for leaks associated with traditional sealed pumps are completely removed.

Product Security – Magnetic drive sealless pumps are the safest and most robust means for liquid transfer. By eliminating the seal, the primary opportunities for leaks associated with traditional sealed pumps are completely removed.

Efficiency – By improving performance and reducing maintenance calls, sealless magnetic drive pumps can dramatically lower downtime and lost production. In sum, this equates to maximised efficiency that can be seen on your bottom line.

Reliability – Sealless magnetic drive pumps have proven their reliability in even the most severe climate conditions, from the frozen tundra of Siberia to the deserts of the Middle East and the humid climes of Louisiana’s refineries. In fact, there are HMD Kontro pumps that have been in operation for over 30 years and are still running today.

Safety – HMD Kontro sealless magnetic drive pumps are manufactured to conform to international design and safety standards, including ATEX, ISO, API and ANSI requirements. Plus, with no mechanical seals to leak hazardous chemicals, these pumps offer a clear choice for process industry professionals who regularly deal with volatile or high value materials.

Cost-effective – Sealless magnetic drive pumps require less monitoring and maintenance than traditional sealed designs, equating to substantial savings over the life of the pump.

Service – Global service centres keep HMD Kontro sealless magnetic drive pumps operating with peak performance. Standard pumps and parts are available from the factory and in the field.

| Heads to | 295 ft |

| Flows to | 370 gpm |

| Maximum Motor Power | 50 Hp |

| Temperature Range | -40 to 500°F |

| Maximum Case Working Pressure | 2700 psi |

| Hydrotest Pressure | 4025 psi |

| Maximum Viscosity | 200 csT |

| Motor Details | Industry standard |

| Solids Range | Maximum of 5% w/w up to 150 microns |

| Mounting Configuration | Close and long coupled |

| Dimensional Standards | N/A |

| Number of Available Hydraulics | 7 |

| Available Flanges | ANSI 300lb / 600lb / 900lb / 1500lb RF / RTJ |

| Heads to | 63 m |

| Flows to | 70 m3/hr |

| Maximum Motor Power | 30 kW |

| Temperature Range | -40 to 260°C |

| Maximum Case Working Pressure | 185 Bar |

| Hydrotest Pressure | 278 Bar |

| Maximum Viscosity | 200 csT |

| Motor Details | Industry Standard |

| Solids Range | Maximum of 5% w/w up to 150 microns |

| Mounting Configuration | Close and long coupled |

| Dimensional Standards | N/A |

| Number of Available Hydraulics | 7 |

| Available Flanges | ANSI 300lb / 600lb / 900lb / 1500lb RF / RTJ |

POWER MONITOR

Installed in the Motor Control Centre (MCC), a power monitor measures the power required to operate the pump. By setting High and Low trip points, the power monitor is the perfect solution for protecting your pump from:

A gas detection system designed to bolster the reliability and eliminate dry-running of HMD Kontro API-685 sealless magnetic drive pumps. This warning system mitigates costly pump component replacements and downtime that can result from dry running, entrainment or cavitation.

A gas detection system designed to bolster the reliability and eliminate dry-running of HMD Kontro API-685 sealless magnetic drive pumps. This warning system mitigates costly pump component replacements and downtime that can result from dry running, entrainment or cavitation.

The VapourView® is powered by an industry standard 24 VDC supply and returns a 4-20 mA signal suitable for monitoring using a distributed control system (DCS). It features both light emitting diode (LED) and liquid crystal displays (LCD) to provide information on process fluid conditions inside of the pump to process engineers.

The VapourView® has been performance tested and is compliant with explosive atmosphere and electro-magnetic compatibility requirements. The VapourView® non-intrusive gas-in-liquid detector can be easily retrofitted into any HMD Kontro API 685 pump and will operate at temperatures between -40 and +350 degrees F (-40 and +180 degrees C).

All HMD Kontro pumps, as standard, can handle up to 5% hard solids and 150 microns diameter. The solid size can increase to 8% solids and 250 microns by fitting a self-cleaning in line filter.

All HMD Kontro pumps, as standard, can handle up to 5% hard solids and 150 microns diameter. The solid size can increase to 8% solids and 250 microns by fitting a self-cleaning in line filter.

For larger solids, HMD Kontro can provide pumps with a clean flush system or filter built into the flush pipework.