Typical Applications Include

- Tanks Farms

- Tank Fluid Transfer

- Chemical Processing Plants

- Petrochemical Processing Plants

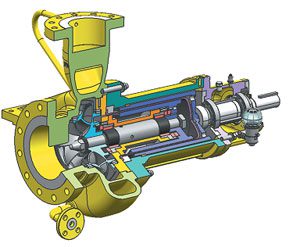

The GSPVS from HMD Kontro is a vertical suspended sealless magnetic drive pump that has all of the benefits in a compact package. It is particularly suited for tank unloading of hazardous and valuable process fluids and is built to API 685 and API 610 specifications and is fully ATEX compliant.

By using ‘Greased For Life’ ball bearings along the column, the requirement for lubrication or cooling of the intermediate sleeve bearings with system fluid is eliminated. Its sealless design uses fewer parts for maximum efficiency and low running costs, maximising online process time.

HMD Kontro GSPVS sealless magnetic drive vertical suspended centrifugal pumps comply with all of the specifications required by the oil & gas, petroleum and heavy chemical industries. The pump is typically used in toxic, aggressive, hot, crystallising and high value processes and the pumps are highly suitable for fuel transfer in oil and gas refineries.

Benefits of the HMD Kontro GSPVS Pump:

| Flows to | 440 gpm (62 m³/hr) |

| Heads to | 1,400 ft (295 m) |

| Maximum Power | 167 HP, 125 kW |

| Temperature Range | -40 to 500°F (-40 to 260°C) |

The GSPVS is composed of modules, which can be joined to reach a total assembly length of up to 16ft (5m) and is mounted on a base available to ANSI B16.5 or any specific customer requirements.

|

Typical Applications Include

|

|

|

Product Security – Magnetic drive sealless pumps are the safest and most robust means for liquid transfer. By eliminating the seal, the primary opportunities for leaks associated with traditional sealed pumps are completely removed.

Product Security – Magnetic drive sealless pumps are the safest and most robust means for liquid transfer. By eliminating the seal, the primary opportunities for leaks associated with traditional sealed pumps are completely removed.

Efficiency – By improving performance and reducing maintenance calls, sealless magnetic drive pumps can dramatically lower downtime and lost production. In sum, this equates to maximised efficiency that can be seen on your bottom line.

Reliability – Sealless magnetic drive pumps have proven their reliability in even the most severe climate conditions, from the frozen tundra of Siberia to the deserts of the Middle East and the humid climes of Louisiana’s refineries. In fact, there are HMD Kontro pumps that have been in operation for over 30 years and are still running today.

Safety – HMD Kontro sealless magnetic drive pumps are manufactured to conform to international design and safety standards, including ATEX, ISO, API and ANSI requirements. Plus, with no mechanical seals to leak hazardous chemicals, these pumps offer a clear choice for process industry professionals who regularly deal with volatile or high value materials.

Cost-effective – Sealless magnetic drive pumps require less monitoring and maintenance than traditional sealed designs, equating to substantial savings over the life of the pump.

Service – Global service centres keep HMD Kontro sealless magnetic drive pumps operating with peak performance. Standard pumps and parts are available from the factory and in the field.

| Heads to | 262 ft |

| Flows to | 308 gpm |

| Maximum Motor Power | 60 HP |

| Temperature Range | -20 to 210°F |

| Maximum Case Working Pressure | 580 psi |

| Hydrotest Pressure | 870 psi |

| Maximum Viscosity | 200 csT |

| Motor Details | Industry standard |

| Solids Range | Maximum of 5% w/w up to 150 microns |

| Mounting Configuration | Close coupled |

| Dimensional Standards | N/A |

| Number of Available Hydraulics | 5 |

| Available Flanges | ANSI 150lb/300lb RF |

| Heads to | 80 m |

| Flows to | 70 m³/hr |

| Maximum Motor Power | 44 kW |

| Temperature Range | -30 to 100°C |

| Maximum Case Working Pressure | 40 Bar |

| Hydrotest Pressure | 60 Bar |

| Maximum Viscosity | 200 csT |

| Motor Details | Industry Standard |

| Solids Range | Maximum of 5% w/w up to 150 microns |

| Mounting Configuration | Close coupled |

| Dimensional Standards | N/A |

| Number of Available Hydraulics | 5 |

| Available Flanges | ANSI 150lb/300lb RF |

POWER MONITOR

Installed in the Motor Control Centre (MCC), a power monitor measures the power required to operate the pump. By setting High and Low trip points, the power monitor is the perfect solution for protecting your pump from:

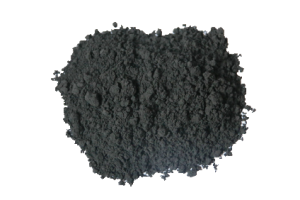

All HMD Kontro pumps, as standard, can handle up to 5% hard solids and 150 microns diameter. The solid size can increase to 8% solids and 250 microns by fitting a self-cleaning in line filter.

All HMD Kontro pumps, as standard, can handle up to 5% hard solids and 150 microns diameter. The solid size can increase to 8% solids and 250 microns by fitting a self-cleaning in line filter.

For larger solids, HMD Kontro can provide pumps with a clean flush system or filter built into the flush pipework.