Increase the performance and life cycle of your sealless pump

ZeroLoss®: A revolutionary containment shell / shroud design to improve efficiency and reduce equipment life cycle costs. ZeroLoss® works by eliminating eddy current heating, a common issue with rotating equipment.

VapourView®: A non-intrusive gas in liquid detector from HMD Kontro that will provide you with vital information of the presence of gases in your pumps internal flow regime and forewarn of any adverse conditions.

Power Control Monitor: A Power Control Monitor (PCM) is a simple electronic device that is easily installed in the electric motor control circuit of any given pump or other rotating equipment representing one of the best ways to protect your pump from system upset damage and avoid costly shutdowns, unexpected repair costs, and premature equipment failure.

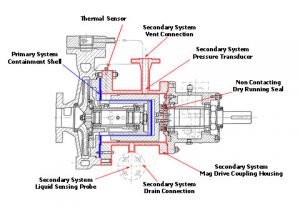

Pressure Containment Shell Surface Temperature Detection: These RTD (PT 100) or thermocouple sensors are permanently mounted on the containment shell and provide real-time monitoring of the temperature inside the magnetic coupling.

Liquid Sensing Probe: This instrument is usually installed in conjunction with a secondary control. It provides an early warning of containment shell failure before dangerous quantities of spillage can fill the coupling housing.

Flow & Liquid Detection: These liquid or flow sensors are mounted at the suction or discharge connection and are designed to prevent pump start-up should the pump not be primed. If the system is allowed to run dry, these detection devices will stop the pump and prevent damage to its components.

Pressure Monitoring: This differential pressure switch is piped across the suction and discharge connections, serving to help monitor system pressure.

Automatic Recirculation Control: An automatic recirculation valve is associated with the pump discharge connection, as a means to provide a permanent bypass in the event of system flow fluctuations or a closed discharge valve. However, the automatic recirculation control will not protect against dry running (please see VapourView®).

Secondary Control: In some process applications, the added benefit of a secondary containment provides even greater protection. HMD Kontro sealless pumps are outfitted with secondary control devices in order to severely restrict any leakage into the immediate locality. Mechanical devices can be fitted to the drive shaft assembly, which are activated in the unlikely event of containment shell failure.

Additionally, the pump coupling housing is also fitted with gaskets to eliminate any leakage across the joining faces. Several of the devices discussed above may also be fitted to the pump as a means of preventing a failure of this magnitude from happening in the first place.

For more information about HMD Kontro and our products including ZeroLoss® containment shells and VapourView®, please call +44 (0) 1323 452000 or email us.