Download a copy of our recently updated guide to the Know How surrounding sealless pumps. They have always had significant benefits, especially thanks to the absolute absence of leaks or emissions. However, these are now coming further to the fore due to recent and more stringent environmental, health and safety requirements. For the Guide to Sealless Magnetic Drive Pumps click here.

Environment, Health and Safety (EHS)

In these days of increasing EHS concerns, and the resulting legislation and litigation, leakages of process product can cause significant problems. Damage can be caused not only to personnel and property onsite, but also to reputations, plus also the loss of production uptime and valuable productivity.

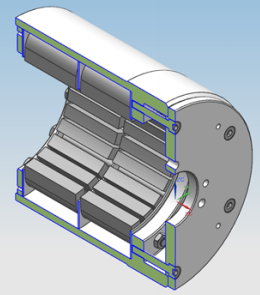

Choose the safe option – a sealless magnetic drive pump

Unlike pumps that include a mechanical seal, which is designed to leak a little for lubrication, but which could also fail, a sealless pump is the safe option. With a sealless pump, the product is completely contained at all times with no potential for leaks, no escapes to the atmosphere, no emissions, no health issues, no safety concerns and no environmental hazards. No How!

A virtual lack of maintenance and repair meaning less downtime

A further advantage of the sealless pump is the almost complete lack of maintenance and repair required. Not only does this reduce the work and requirement for routine and replacement parts, it also eliminates the associated downtime.

Sealless pumps are now an option on new applications

You may be surprised. The capabilities and operating parameters for sealless pumps may well now be much higher than you think. As a result, they are finding many new applications and are often being used on installations where traditional mechanical sealed pumps would be first considered.

Download Your Guide To Sealless Magnetic Drive Pumps

As the instigators of the sealless pump concept, HMD Kontro have an unparalleled understanding of the magnetic drive process and its benefits. As a result, we have recently updated our Know-How Guide that explains these savings in further detail.

Download a copy today by clicking here.