Hydrofluoric acid alkylation poses particular challenges to process operators, requiring special care in the handling of HF Acid, a lethal, highly corrosive fluid that poses a potential hazard to plant equipment, the people who work on site and the wider environment should a leak occur.

HF Alkylation combines olefins (primarily a mixture of propylene and butylene) with isobutene in the presence of a hydrofluoric acid catalyst to produce alkylate: a high-octane additive and critical safety component that offsets the high vapour pressure of the ethanol mandated in today’s low-sulphur unleaded petrol and gasoline supplies.

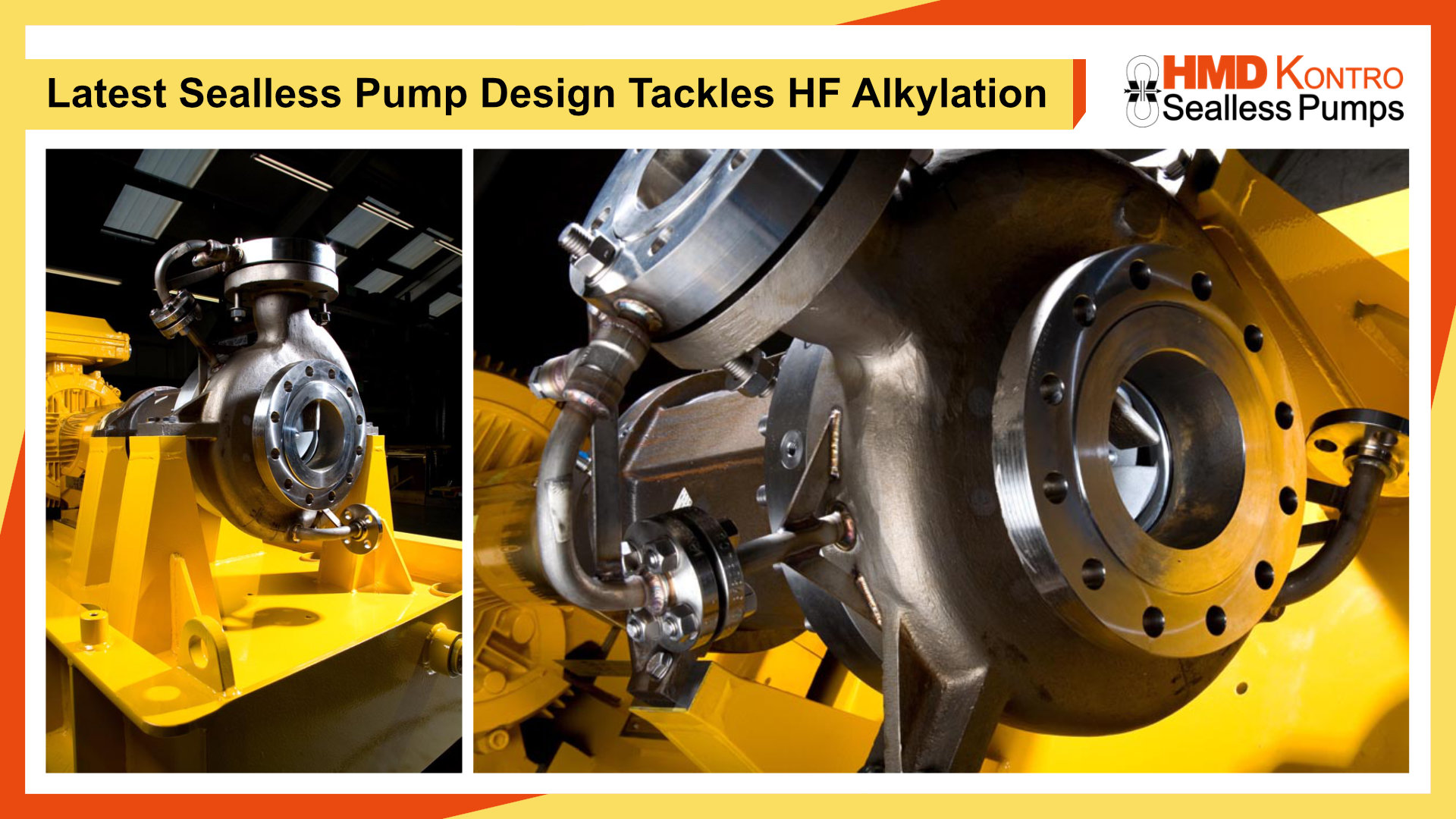

As reviewed online by World Pumps, HMD Kontro’s next generation pumps have been refined using new materials and technologies to provide an effective solution. The result of close collaboration between UOP Honeywell, the leading licensor of HF alkylation technology and using an innovative development process, the HMD Kontro HF pump features a high integrity pump casing manufactured from Alloy C22 (ASTM A194 Gr. CX2MW).

This has been tested using new methods of Non-Destructive Examination (NDE) and has been proven to offer the necessary resistance to corrosion to meet NDE standards. In addition, the pump’s secondary containment system is rated to 40 bar (580 psi), eliminating the possibility of leakage into the environment, and reducing operational risks and the associated costs to meet the industry’s stringent environmental and health and safety goals.

Read the full story on the World Pumps website. For more information, please see our HF Alkylation page.