Think Sealless represents HMD Kontro’s passion to inform the process industry about this engineering revolution and the benefits of magnetic drive pumps over traditional sealed pumps, including those with complex and costly seal support systems.

Why buy a pump that leaks? How long is it since you evaluated the considerable cost savings and safety benefits of a sealless, magnetic drive pump against the traditional type of pump, which depends upon seals, with their inherent risk of leaks, to maintain integrity and contain your product? If it is some while, you may be surprised at how often sealless is now the solution, and how making a step change in your process technology could benefit your business.

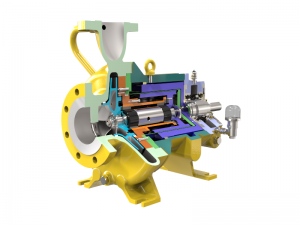

Sealless pumps are essentially conventional centrifugal pumps without packed glands or seals. The seal is replaced by a static containment shell or shroud to form a completely sealed liquid end or pressure boundary.

Sealless pumps are easier to maintain, have fewer working parts, no potential leak paths and no support systems to design, install and maintain. Maintenance is simple, and the life cost is significantly lower than that of a mechanical sealed pump.

Thanks to a modular construction and the ability to dismantle HMD Kontro sealless pumps without special tools, servicing of the pumps on site is simple and straightforward.

When it comes to applications in the chemical, oil, petroleum, gas production, pharmaceutical and general process industries that involve toxic, fine, corrosive and aggressive liquids, our sealless magnetic drive pumps deliver the rock solid, dependable, and reliable performance that engineers demand and that industrial regulations require.

To find out more please click on the band of green icons in the header of this website.