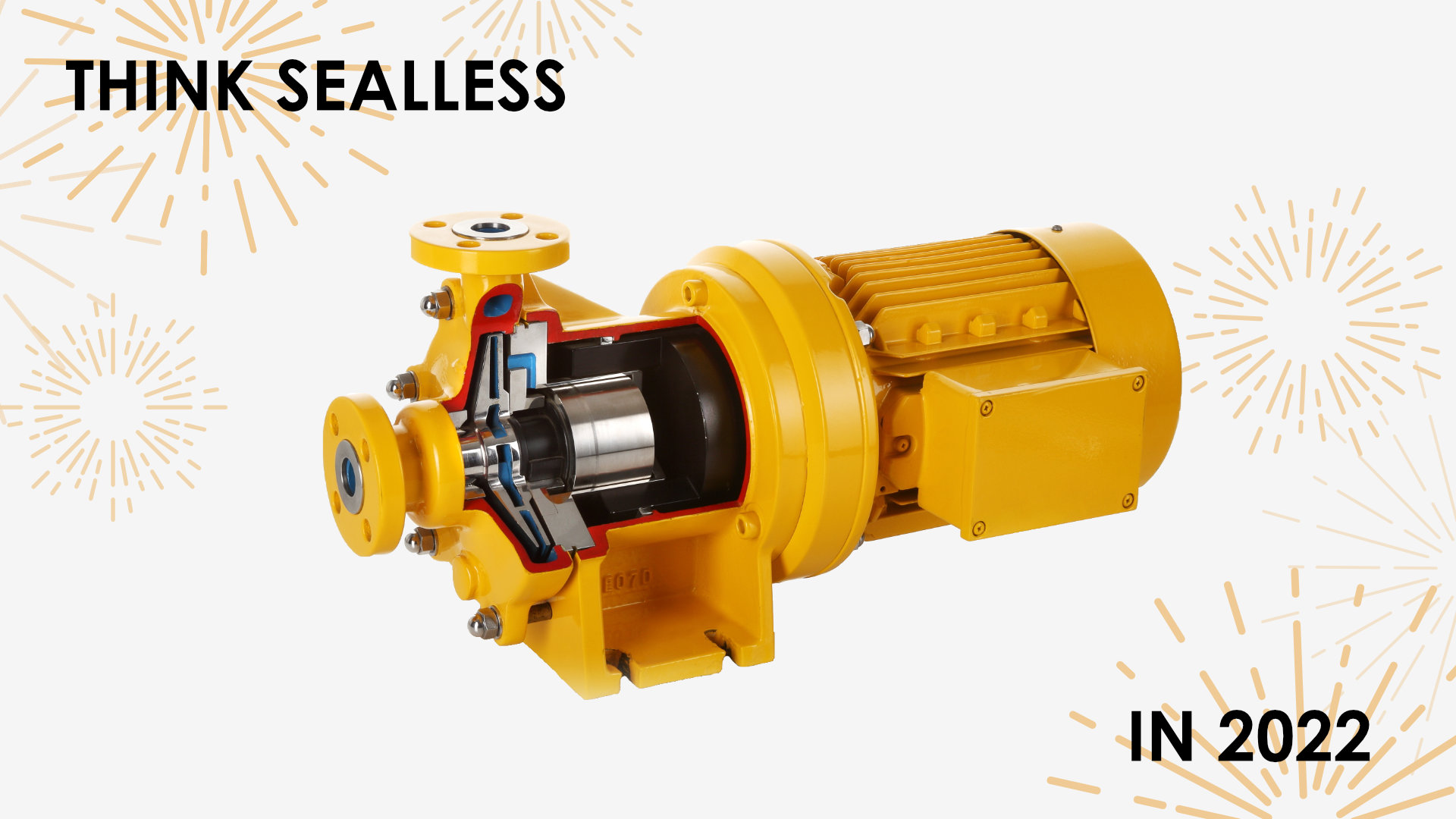

Why sealless pumps are the smart choice

Magnetic drive sealless pumps have many key design features for increased reliability, cost-effectiveness, enhanced safety and are very environmentally friendly. In addition magnetic drive pumps save time and cost on design, installation and operation.

By specifying an HMD Kontro sealless pump you can be absolutely positive that you have made the right decision. Combining cutting edge technology with over seventy years of expertise and experience, since we were the first in the world to develop the concept, our pumps provide complete peace of mind.

- Completely Contained Sealless Design

- Single Joint Casing and Containment Shell

- High Efficiency Magnetic Couplings & Wet End

- Modular Rotating Element Cartridge

- Fully Confined Casing Gasket

- Robust Magnetic Coupling

- Wide Choice of Materials

- Universal Connection Options

- Interchangeable Components

HMD Kontro pumps are built to last. We have many examples of extended pump life across our seventy year history, we have more experience than any other manufacturer. In many installations, HMD Kontro have run without maintenance for ten years and often even more.

In most HMD Kontro pumps we use silicon carbide bearings, a material so hard that under normal process and conditions it will not wear for many years. When you add permanent samarium cobalt magnets and the unique way we engineer our pumps, this results in a very long service life with minimal maintenance and cost.

Think Sealless – Please visit www.thinksealless.com