Upgrading to an even safer pump solution

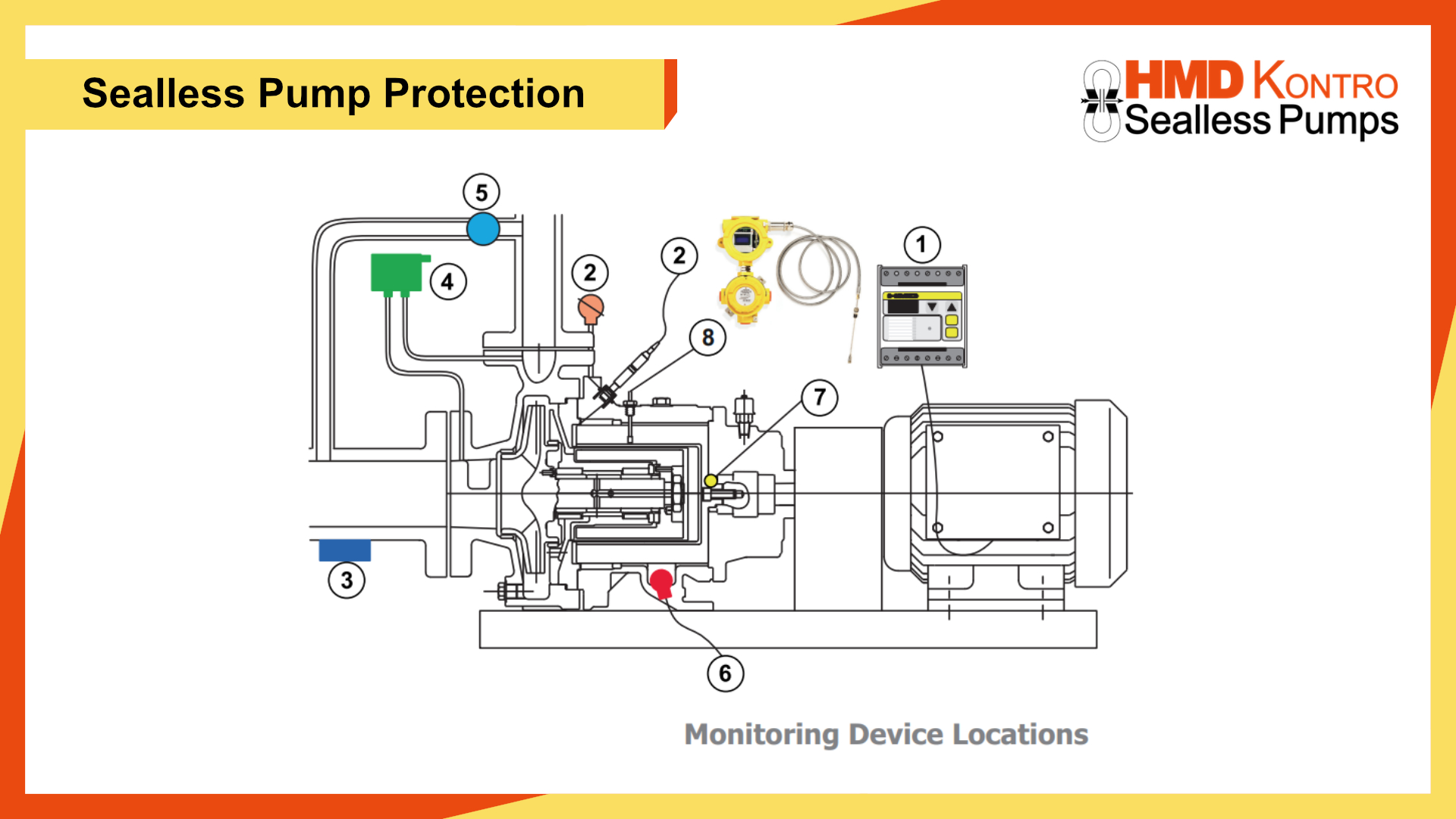

Sealless magnetic drive pumps offer complete containment and eliminate the need for dynamic seals. The containment shell forms part of the primary pressure boundary, and its breach is an extremely rare occurrence. To further enhance safety when pumping hazardous liquids, HMD Kontro sealless pumps can be fitted with secondary protection as an upgrade to restrict or contain any leakage.

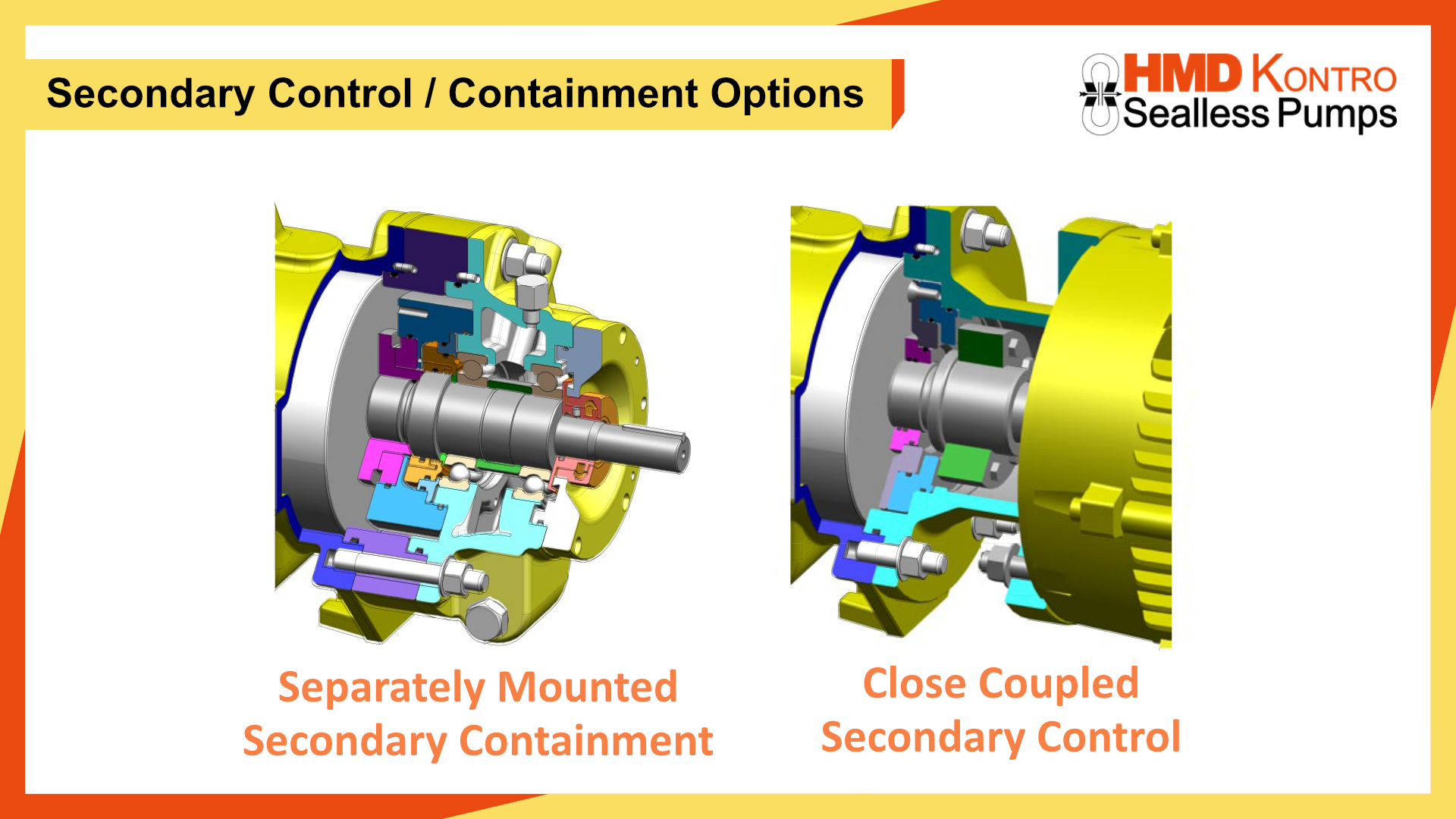

There are two methods of secondary protection:

Secondary Containment

The containment shell is located inside the coupling housing which may, as an option, be fully sealed to form a secondary pressure boundary with a secondary containment system. The system comprises a dry-running gas seal at the rear of the coupling housing along with a leak detection device (either Pressure or Liquid Sensor) in the secondary area. If the primary pressure boundary fails, the pump is shutdown, and the process liquid is contained.

Secondary Control

As a variation on the above containment option, secondary control features a sealing device at the rear of the coupling housing that restricts leakage, along with leak detection instrumentation (either Pressure or Liquid Sensor) within the secondary area. In the unlikely event of a breach of primary containment, liquid release is restricted, and the system allows for the removal of the process liquid via the secondary housing vent or drain connections.

HMD Kontro has a wide range of aftersales literature to help you with your HMD Kontro products. If you would like further information about secondary control and containment please take a look at our Secondary Control Containment leaflet or send an email to info@hmdkontro.com.