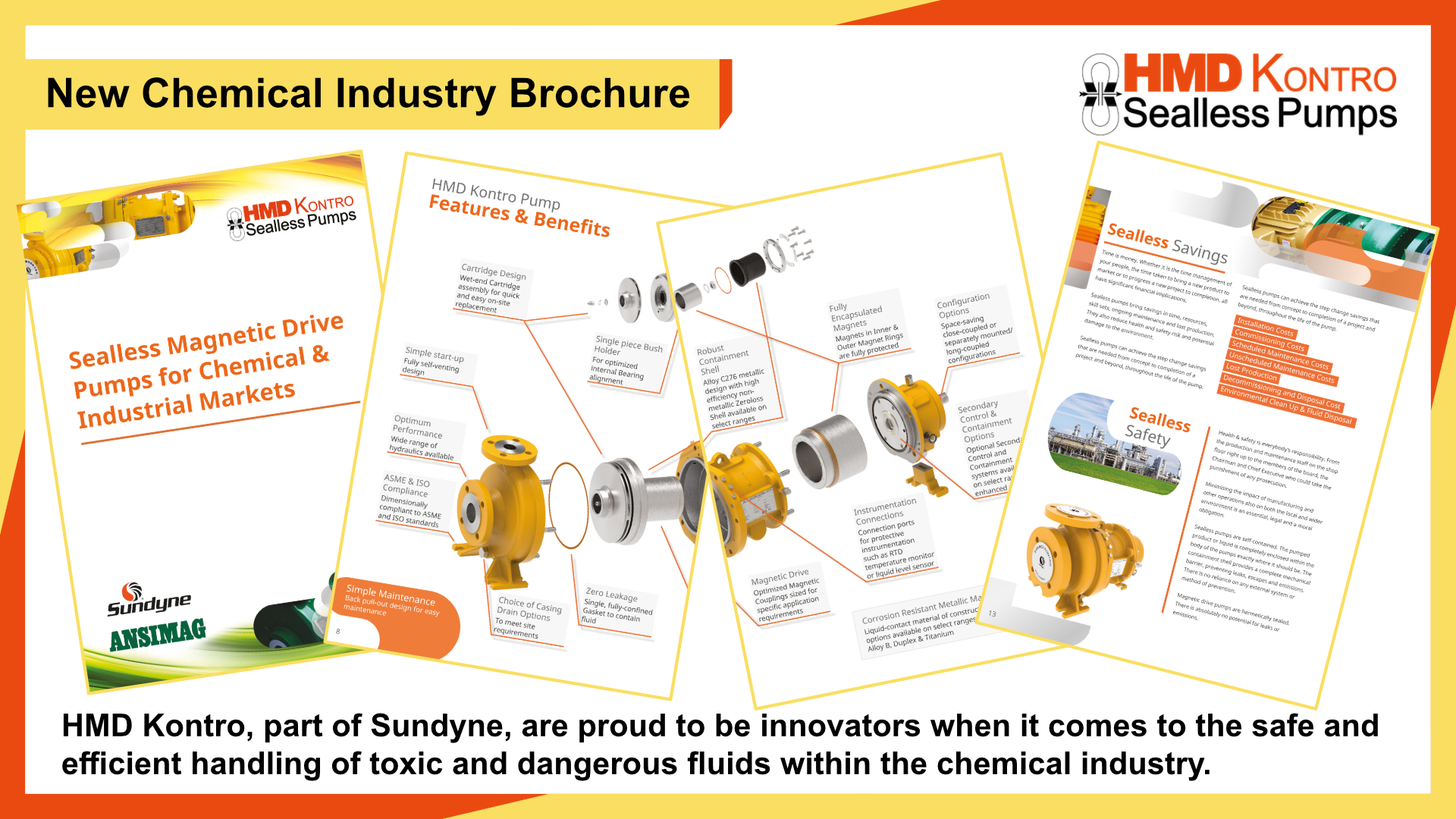

HMD Kontro, part of Sundyne, are proud to be innovators when it comes to the safe and efficient handling of toxic and dangerous fluids within the chemical industry.

Our sealless magnetic drive pumps can handle high temperatures, high pressures and volatile, corrosive, carcinogenic and aggressive substances found within chemical pump applications such as chlor-alkali, solvents, inorganic chemicals, pesticides, insecticides, herbicides, fertilisers, and many others. Providing total fluid containment with no seals or seal support systems, HMD Kontro pumps deliver the highest levels of safety and environmental protection.

Our new chemical brochure showcases the wide range of chemical service sealless pumps available from HMD Kontro and ANSIMAG and is also available to view and download.

The brochure includes details of our recently expanded HMD Kontro CSI ISO metallic sealless chemical service pump range, alongside the recently launched ANSIMAG ALI ISO ETFE-lined sealless pump. Together, HMD Kontro and ANSIMAG offer an extensive range of ISO compliant sealless magnetic drive pumps for a wide variety of challenging chemical processing applications.

To view and download the new brochure, please see the Brochures section in our Resources hub.