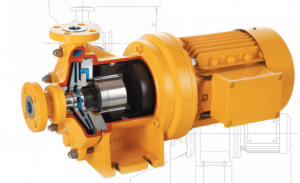

Uptime continuity and resolving any pump maintenance issues quickly onsite are vital and so then Insurance Spares Kits from HMD Kontro are designed to fulfil these requirements.

Comprehensive Analysis of the Spare Parts You are Most Likely to Need

With over 70 years of sealless magnetic drive pump experience, our technical team has carried out comprehensive analysis of the most common maintenance and repair issues that you may encounter. As a result, we have developed a broad portfolio of spare parts kits to ensure the fast, simple and economical maintenance of your sealless pumps, onsite.

A Conveniently Packaged Kit Offering Great Value for Money

Our Insurance Kits represent great value as they come at a discounted price when compared with the sum of the individual parts contained. Within the conveniently packaged kit, are an internal and outer magnet ring, a containment shell, lubricated bearings, gaskets and O-rings. You can simply replenish the kit when parts are used.

For more information and to receive a leaflet about the Insurance Spares Kit, please call us on +44 (0)1323 452154 or email us