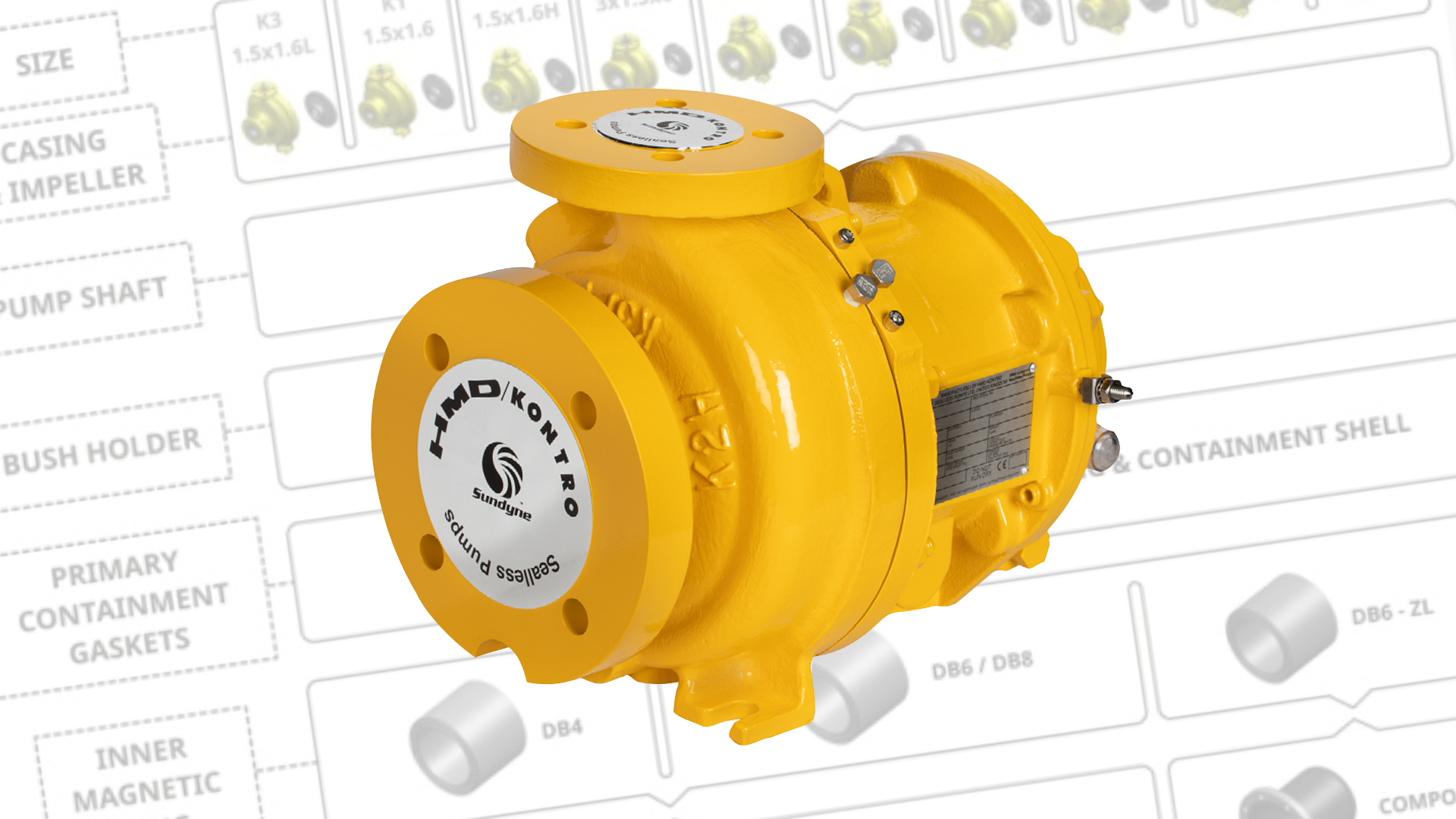

The new HMD Kontro CSA/CSI range of pumps represents a significant leap in sealless pump technology with its modular design and interchangeability of component parts. Specifically designed for ease of configuration and upgrade, the range has been developed to maximise uptime while delivering cost savings through improved lead times and operational efficiencies.

CSA/CSI Modularity = Versatility / Reliability / Safety / Serviceability / Availability

The new CSA/CSI range is distinguished by its extremely wide operating parameters. The extended space and shaft design of its new external bearing assembly provides resistance at temperatures from as low as -40°C/F up to 260°C / 500°F. Withstanding design pressures of up to 19.0 bar / 275 psi at 38°C / 100°F, the CSA / CSI pumps offer flow rates up to 77 m³/h / 340 USgpm and can process liquids with a viscosity from 0.1 – 200 cSt.

A wide range of high-efficiency hydraulics ensure maximum flow and head coverage for optimal productivity. Low and high hydraulic variants are available to ensure an optimised fit, improving production flow rates and delivering cost savings.

The ‘Frame 1’ naming convention denotes a pump with B73.3 dimensional designations making the CSA/CSI an excellent upgrade path for switching from a mechanically sealed to a sealless pump. Think Sealless!

Please visit the CSA/CSI section of the website for more information, including detailed product specifications, then contact us for where you can purchase or with any questions.