Sealless Application Information: Magnetic Drive pumps help meet the demand for high safety levels within the global battery manufacturing industry.

The battery manufacturing industry is experiencing unprecedented changes in demand, where the pursuit of production capacity, improved battery performance, new technologies, and profitability are at the forefront of future industry thinking.

Global battery manufacturers are looking to produce reliable and high-performing lithium-ion batteries and one area of concern is the safety of plant workers during a manufacturing process that involves the handling of aggressive chemicals.

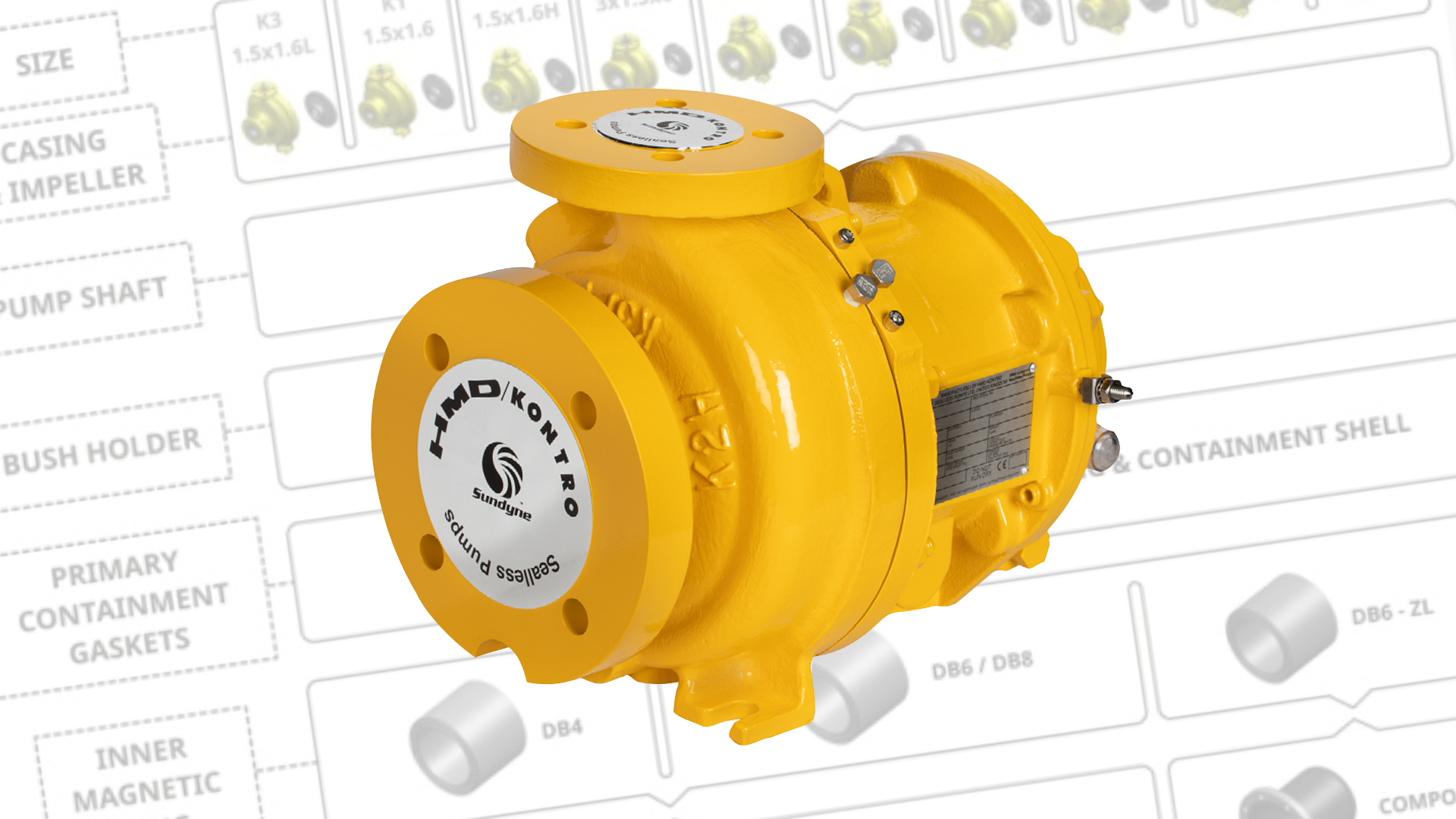

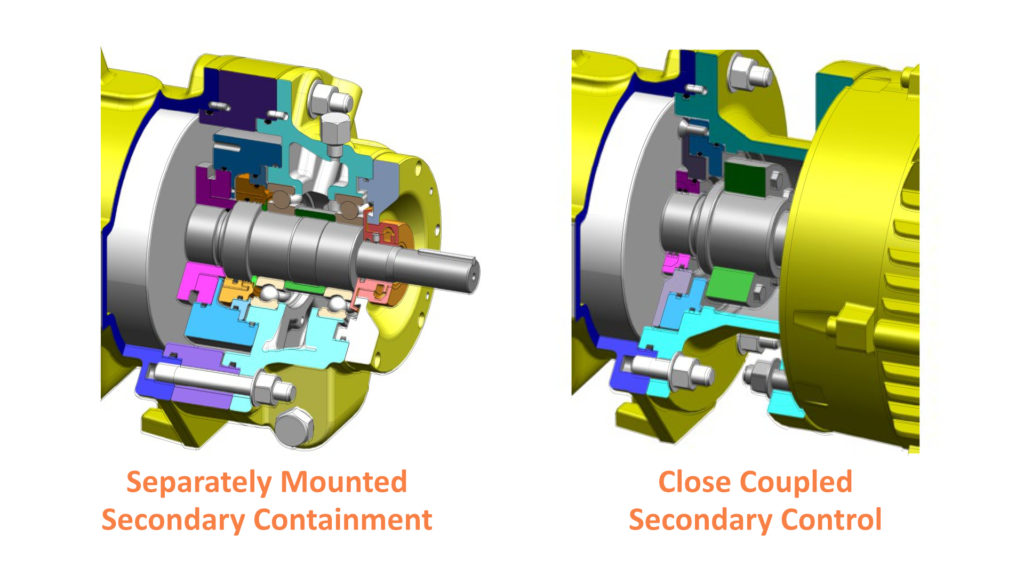

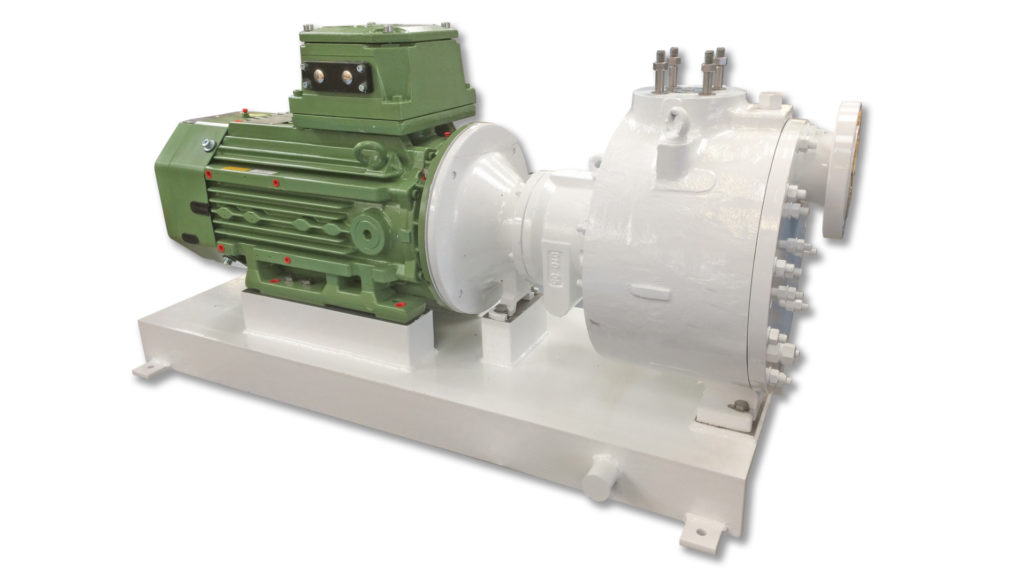

As specialists in the provision of magnetic drive pumps, in industries where performance and environmental integrity are key, HMD Kontro has a keen understanding of these manufacturing priorities. Our sealless magnetic drive pumps provide an effective alternative to traditional mechanical seal pumps, offering multiple benefits ranging from leak-free operation to minimal maintenance requirements.

For each of our global battery manufacturing clients we ensure that we meet all aspects of their manufacturing needs:

- Careful handling of flammable, combustible, or toxic chemicals

- Reliable solutions that deliver high operational uptime and require minimal maintenance

- Responsive and flexible global supply with quick delivery capability to worldwide manufacturing plants

- Compliance to industry standards including ASME B73.3, ISO 2858 / 15783, API 685 and ATEX

HMD Kontro pumps are compatible with a range of process liquids, including aggressive liquids and solvents that require careful handling plus an important need for sensitivity to the environment in which they are used.

For more information on how HMD Kontro’s sealless pumps can integrate into battery manufacturing production methods and provide reliable, durable, and safe liquid pumping solutions, please see our dedicated Battery Manufacturing page.