With the introduction of additional models to our CSI chemical service pump range, we are expanding our ISO sealless magnetic drive pump offering and meeting the needs of an even wider range of chemical pump applications.

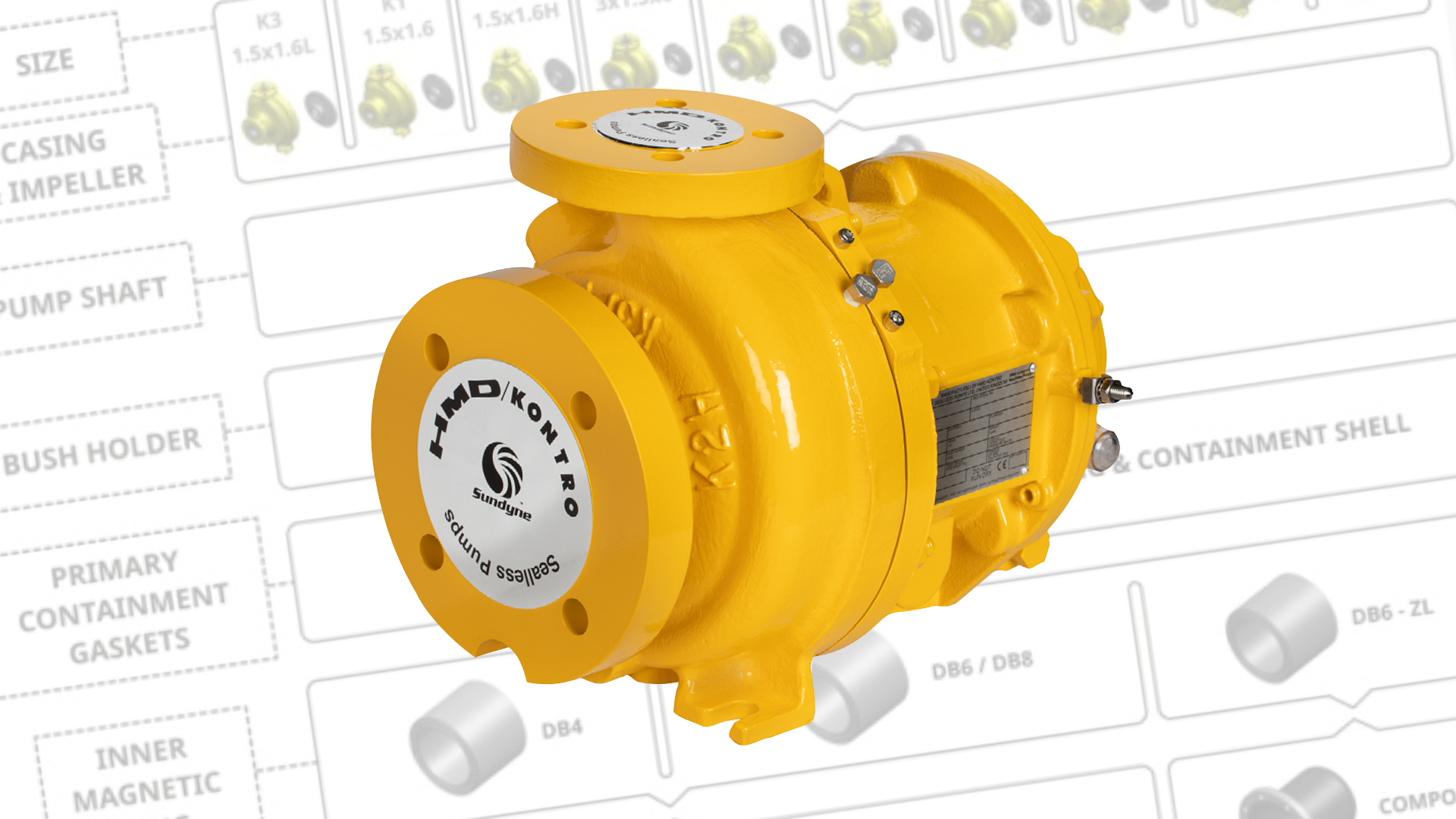

The CSI chemical service sealless magnetic drive pump range has been expanded to include additional models, providing comprehensive hydraulic coverage with a total of 13 Frame 1 and 16 Frame 2 sizes. Meeting ISO dimensional and construction standards 2858 and 15783, the expansion of the CSI range has focused primarily on additional hydraulics and a feature set which allows greater variation in the inlet and outlet sizes, allowing a wider range of flow rates of up to 120 m3/h and heads up to 62m, all optimised for high performance.

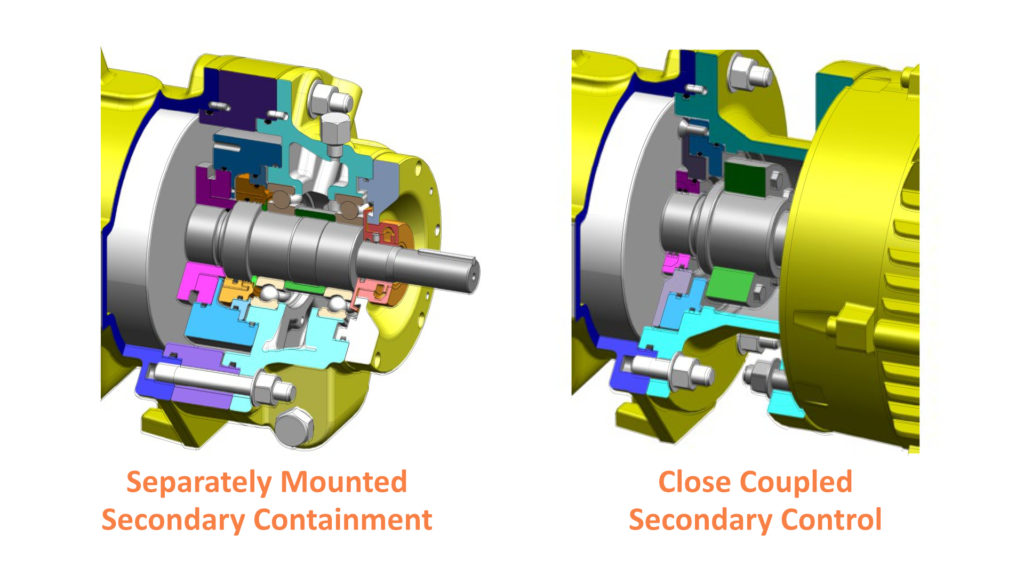

HMD Kontro’s CSI sealless pumps set the standard for metallic magnetic drive ISO pumps. With space-saving close-coupled or separately mounted/long coupled configurations, the CSI range is specifically designed to handle aggressive, corrosive, or acidic liquids in chemical applications. With zero leaks or product emissions, the CSI magnetic drive pump is well suited to many of the pumping services found within these chemical facilities including the processing of chlor-alkali, agricultural chemicals, fine and inorganic chemicals, isocyanates, plastics, and polymers. Also, within other manufacturing industries such as battery manufacturing, water and wastewater, and petro-chemicals.

“The expansion of the CSI range ensures that we can continue to offer a world class chemical pumping solution for the ISO markets with not only the highest levels of robustness in the field but with an enhanced customer driven feature set. We can also maintain maximum pump configurability with rapid availability regardless of the specification needed” explains Hannah Verrall, Product Line Manager, HMD Kontro.

The CSI range is engineered specifically to deliver high performance and superior safety when pumping hazardous fluids. Key benefits of the CSI and other HMD Kontro sealless magnetic drive pumps include:

- Total fluid containment providing better environmental protection and operator safety

- No seals or support systems eliminating possible leakage and resulting pump downtime

- Dimensionally interchangeable options for existing installations for a more simplified procurement and commissioning process

- Global availability and full online selection and configuration capabilities

In addition, the CSI range comes with a wide range of additional features that can be selected especially for applications requiring an additional layer of protection including Secondary Control/Containment, and the ZeroLoss containment shell, which significantly improves efficiency.

Complimenting the HMD Kontro CSI line is the new Ansimag ALI line of non-metallic lined sealless magnetic drive pumps. All Ansimag wetted parts are moulded ETFE (Ethylene Tetrafluoro Ethylene) components that can safely handle a wide range of corrosives and solvents without corrosion.

For more information, please visit our CSI Frame 1 sealless pump page.